The iGR-FH laser cutting machine can choose a variety of cutting areas: 1300mm*2500mm, 1500mm*3000mm, 1500mm*4500m, 2000mm*4000mmmm, and 2500mm*6000mm, and can also customize the cutting area according to customer requirements.

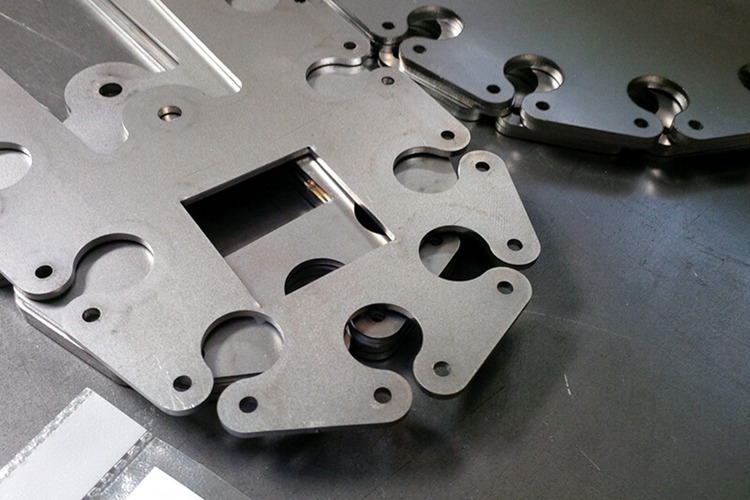

Sheet Metal Laser Cutter

The sheet fiber laser cutting machine is a laser cutting machine specially designed for sheet metal, which uses a fiber laser generator as power. It uses the newly developed fiber laser generator, which can output a high-energy-density laser beam on the surface of the workpiece, melt and vaporize the area irradiated by the laser, and realize high-speed, high-precision perfect automatic cutting.

Most CNC laser cutting machines have a processing range of 0.3 mm to 25 mm, which is suitable for higher power models. The laser cutting machine can cut a variety of materials, including low carbon steel, stainless steel, aluminum, zinc steel, pre-galvanized steel, copper, brass, etc. CNC laser cutting uses various gases to assist the cutting process, including compressed air, nitrogen, and oxygen.

Laser Sheet Metal Cutter Advantages

Using a laser cutter for sheet metal offers numerous benefits:

- Precision: Achieve intricate designs with tolerances as tight as ±0.001 inches.

- Speed: Faster cutting speeds compared to traditional methods like plasma or waterjet cutting.

- Versatility: Suitable for various metals, including stainless steel, aluminum, brass, and copper.

- Minimal Waste: Optimized cutting paths reduce material waste.

- Automation: Many laser cutters are equipped with CNC (Computer Numerical Control) systems for automated and repeatable operations.

- The laser head adopts two-point centering adjustment, and the focusing mechanism is driven by servo motor, which can significantly improve the piercing efficiency.

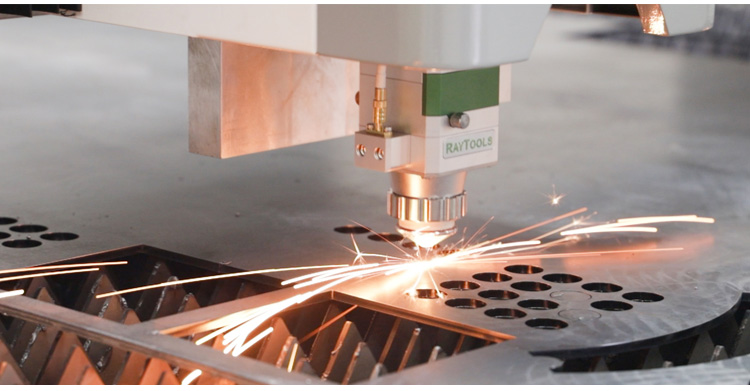

IGOLDEN Cutting Head

By optimizing the structural design of the cutting head to extend its service life,

Dual dust protection design, eliminate lens contamination risk, improve user experience.

Intelligent Control System

FANGLING plane cutting software is a set of software specially developed for the deep customization of the laser cutting industry, easy to use, rich in functions, suitable for various processing occasions.

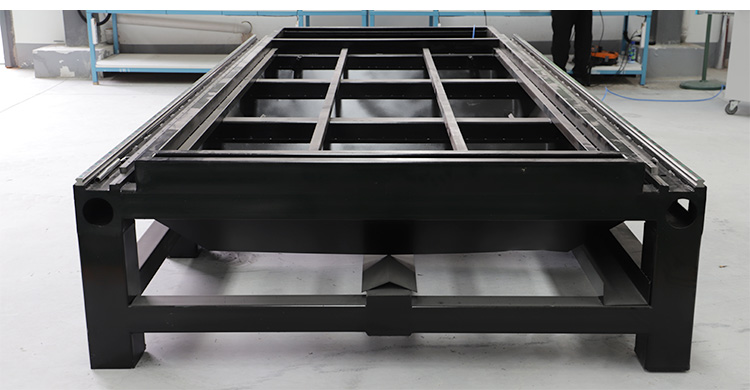

Heavy-duty Welding Body

Higher tensile strength and dimensional stability, Effectively improve the accuracy of the bed, reduce the processing error of the workpiece.

Max Laser Source

Small weight, light weight, easy integration, high performance, more stable processing; The optical path module has good protection and high safety.

Application of Fiber Laser Cutting Machine

Laser cutting machines can quickly cut alloys, carbon steel, stainless steel, copper, aluminum, gold, silver, and titanium, making them ideal for diverse industries. They are frequently employed in manufacturing billboards, electrical enclosures, fences, doors, windows, and building materials. Additionally, their precision and efficiency make them indispensable for producing automotive panels and components, ensuring high-quality results across various applications.