Guar, derived from the seeds of the guar plant, is a versatile and valuable crop with a wide range of industrial and commercial applications. Known for its role in producing guar gum, an essential thickening and stabilising agent, it serves industries like food, pharmaceuticals, textiles, and oil drilling. Establishing a guar manufacturing plant in 2025 offers a lucrative opportunity, leveraging the increasing demand for this multifunctional ingredient. This article delves into the essentials of setting up a guar manufacturing facility, from raw materials to production processes and market trends.

Market Overview

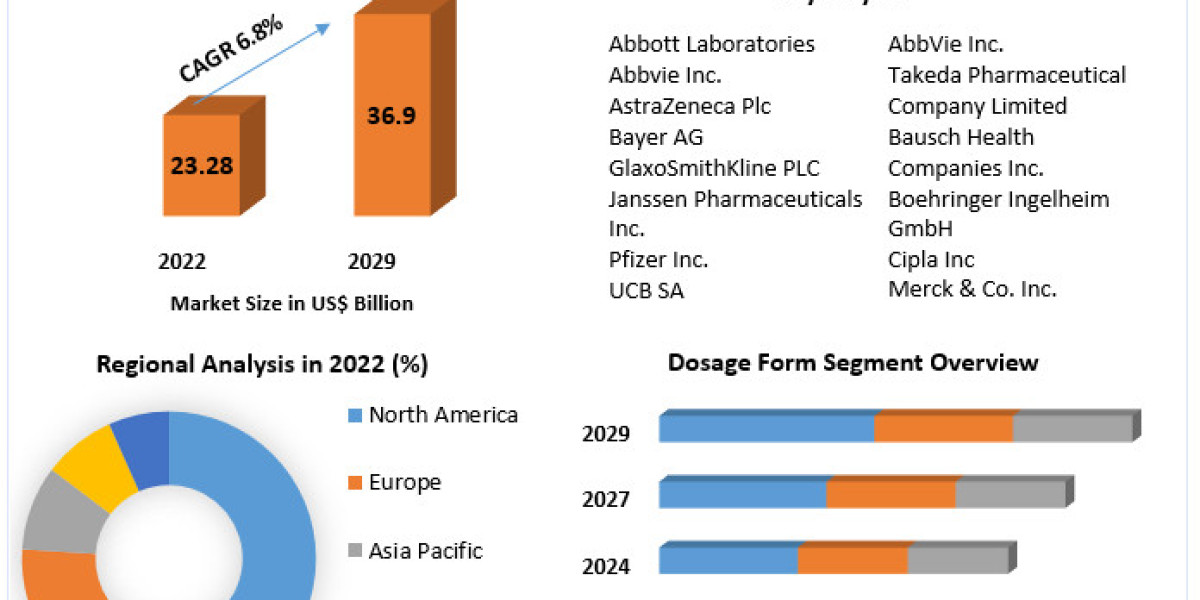

The guar market has witnessed steady growth due to its extensive applications in various industries. The food industry relies heavily on guar gum as a thickener and emulsifier, while the oil and gas sector uses it in hydraulic fracturing operations. The Asia-Pacific region, particularly India, dominates the global guar production, with increasing demand in North America and Europe driving market expansion. The rising focus on natural and plant-based ingredients further boosts the demand for guar and its derivatives.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/guar-manufacturing-plant-project-report/requestsample

Key Raw Materials

- Guar Seeds: The primary raw material, sourced from guar plants cultivated in arid and semi-arid regions.

- Water: Essential for processing guar seeds and extracting guar gum.

- Additives: Used to enhance the quality and stability of the final product.

Manufacturing Process

The production of guar gum involves several key steps to ensure high-quality output:

- Seed Cleaning: Raw guar seeds are cleaned to remove dirt, stones, and other impurities.

- Dehusking and Splitting: The outer husk is removed, and the seeds are split into smaller parts.

- Grinding: The splits are ground into a fine powder to produce guar gum.

- Screening and Purification: The powder is sieved and purified to achieve the desired quality and consistency.

- Packaging: The final product is packed in moisture-proof bags or containers for storage and distribution.

Plant Setup Essentials

- Location: Choose a site near guar-growing regions to minimise raw material transportation costs.

- Machinery: Invest in cleaning, splitting, grinding, and packaging equipment designed for guar processing.

- Skilled Workforce: Employ experienced technicians and operators to manage production processes.

- Utilities: Ensure uninterrupted access to water, electricity, and storage facilities.

- Environmental Compliance: Adhere to local environmental regulations and implement waste management systems.

Applications of Guar

- Food Industry: Used as a thickener, stabiliser, and emulsifier in dairy products, sauces, and baked goods.

- Oil and Gas Sector: Plays a critical role in hydraulic fracturing operations as a gelling agent.

- Pharmaceuticals: Applied in tablet formulations and as a binding agent in drug production.

- Textiles: Acts as a sizing agent to improve the finish and strength of fabrics.

- Personal Care: Used in shampoos, conditioners, and lotions for its thickening and stabilising properties.

Safety Considerations

- Worker Safety: Provide protective equipment and training to handle machinery and raw materials.

- Dust Control: Install dust extraction systems to minimise air contamination during grinding and screening.

- Storage Conditions: Store guar seeds and processed guar in cool, dry areas to maintain quality.

- Emergency Protocols: Develop plans for handling equipment malfunctions or fire hazards.

Challenges in Manufacturing

- Raw Material Dependency: Reliance on guar-growing regions can impact raw material availability and costs.

- Quality Control: Ensuring consistent product quality across batches requires advanced machinery and strict monitoring.

- Market Competition: Competing with established players necessitates innovation and superior product standards.

- Regulatory Compliance: Meeting food-grade and industry-specific standards can increase production complexity.

Opportunities in the Industry

The growing demand for natural and plant-based ingredients presents significant opportunities for guar manufacturers. Expanding into value-added guar products like hydroxypropyl guar and fast-hydrating guar gum can enhance market potential. Collaborating with food and oil industry leaders for customised solutions can also increase revenue. Moreover, focusing on sustainable farming practices and eco-friendly production techniques can attract environmentally conscious consumers.