In today’s fast-paced industrial world, every component in a system plays a crucial role in ensuring seamless operations. Among these, hand lever valves stand out as an indispensable tool for professionals seeking efficient and user-friendly control over pneumatic and hydraulic systems. In this post, we will explore how hand lever valves simplify your workday, enhance control, and reduce stress, making them a preferred choice in various industries.

What is a Hand Lever Valve?

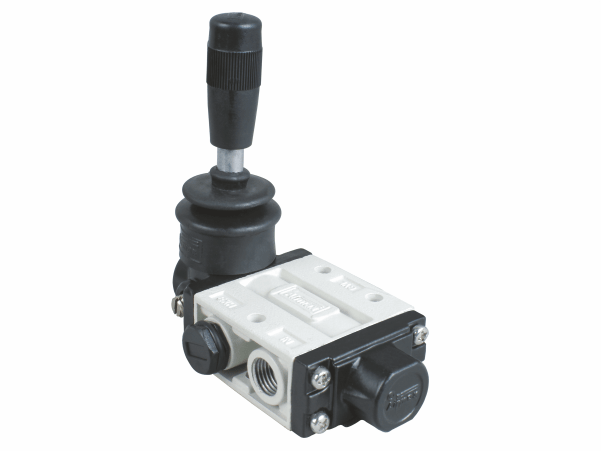

A hand lever valve is a manually operated device designed to control the flow of air or fluid in a system. With its ergonomic design and intuitive functionality, it allows users to regulate operations with precision. Available in various configurations such as 2-way, 3-way, and 5-way, hand lever valves cater to diverse industrial needs.

Key Features That Simplify Your Workday

1. Ease of Operation

Hand lever valves are straightforward to operate. With a simple push or pull of the lever, you can activate or deactivate the flow, ensuring minimal effort during use. This ease of operation reduces operator fatigue, making long workdays less daunting.

2. Reliable Control

These valves provide precise control over fluid or air flow, enabling users to fine-tune operations. Whether you’re managing a pneumatic system or directing hydraulic fluid, the consistent performance of a hand lever valve ensures stress-free operations.

3. Durable Construction

Built from high-quality materials like stainless steel, brass, or aluminum, hand lever valves are designed to withstand harsh industrial conditions. This durability minimizes the chances of unexpected breakdowns, allowing you to focus on your tasks without worrying about frequent repairs.

Stress-Reducing Benefits of Hand Lever Valves

1. Ergonomic Design for Comfort

The ergonomic design of the lever reduces strain on the user’s hand and wrist, especially during repetitive operations. This thoughtful construction ensures operators can work efficiently without discomfort, enhancing workplace productivity.

2. Time Efficiency

Manual control via a hand lever valve is faster compared to complex automated systems. This saves time during routine operations, helping teams meet deadlines with ease.

3. Improved Safety

Hand lever valves allow operators to shut off the flow quickly in case of an emergency. This swift response capability adds an extra layer of safety, reducing workplace stress.

Applications Where Hand Lever Valves Shine

Hand lever valves are versatile tools used across industries, including:

- Manufacturing: For controlling pneumatic tools and machinery.

- Automotive: In hydraulic brake and clutch systems.

- Agriculture: Managing irrigation and fluid transfer systems.

- Construction: Used in heavy equipment for fluid control.

Their adaptability makes them a valuable addition to any operational setting.

Tips for Choosing the Right Hand Lever Valve

To ensure maximum efficiency and stress-free operations, consider the following factors when selecting a hand lever valve:

Pressure and Temperature Ratings

Ensure the valve can handle the pressure and temperature conditions of your system. For instance, valves with a pressure rating of 10 Kg/cm² and a temperature range of up to 80°C are suitable for most industrial applications.Material Compatibility

Select a valve material that is compatible with the medium it will control. For corrosive fluids, stainless steel is a preferred choice.Valve Size and Configuration

Choose the appropriate size (e.g., 1/4", 1/2") and configuration (e.g., 3-way or 5-way) based on your system requirements.Brand and Quality Assurance

Opt for valves from reputable manufacturers to ensure quality, reliability, and post-purchase support.

Maintenance Tips for Longevity

Proper maintenance is key to keeping your hand lever valve in top condition:

- Regular Cleaning: Prevent dust and debris from clogging the valve.

- Lubrication: Apply appropriate lubricants to ensure smooth operation of the lever.

- Inspection: Periodically check for wear and tear to address issues before they escalate.

By following these maintenance practices, you can extend the lifespan of your hand lever valve and enjoy stress-free performance for years.

Why Choose Hand Lever Valves?

In an era where automation dominates, hand lever valves offer a balance of simplicity and reliability. Their manual operation empowers users with direct control, reducing dependency on complex systems that may fail unexpectedly. Whether you're a technician in a factory or an engineer on a construction site, a hand lever valve ensures you’re always in control.

Conclusion

Hand lever valves are more than just components in a system—they are tools that enhance productivity, simplify operations, and foster a stress-free working environment. By choosing the right valve for your needs and maintaining it properly, you can ensure seamless operations and peace of mind throughout your workday.

Are you looking for high-quality hand lever valves for your applications? Contact [Your Brand/Company Name] today and experience the difference they can make in your operations!