eosynthetics have transformed the landscape of civil engineering and construction, offering innovative solutions for soil stabilization, erosion control, and infrastructure reinforcement. Among these advancements, geosynthetic rollers stand out as a critical technology. These devices have significantly improved the efficiency, cost-effectiveness, and environmental sustainability of various projects. This article delves into the world of geosynthetic rollers, exploring their applications, benefits, and the future of this remarkable technology.

What Are Geosynthetic Rollers?

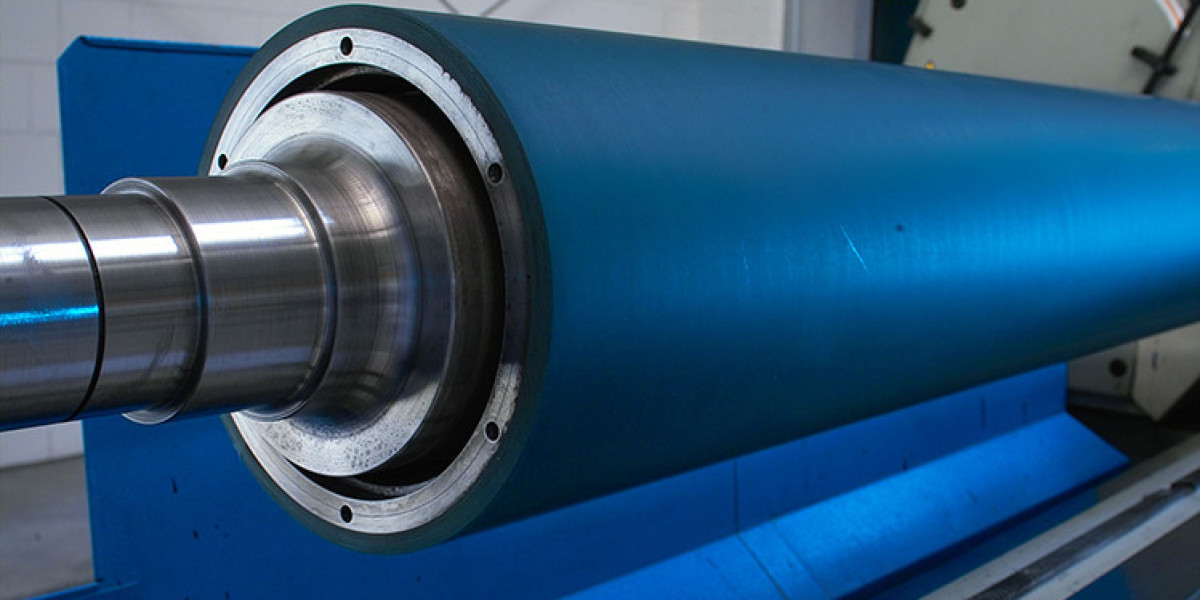

Geosynthetic rollers are cylindrical devices used to install geosynthetic materials, such as geotextiles, geomembranes, and geogrids, in construction and environmental engineering projects. These rollers are typically designed to unwind and lay these materials smoothly and uniformly over large surfaces. The primary purpose is to facilitate the integration of geosynthetics into projects, enhancing soil stability, reducing erosion, and providing structural reinforcement.

Key Applications

Road Construction and Maintenance

- Geosynthetic rollers are widely used in road construction to improve pavement performance and longevity. By reinforcing the subgrade and distributing loads more evenly, these materials reduce the risk of rutting and cracking, leading to longer-lasting roads.

Erosion Control

- In projects aimed at preventing soil erosion, such as riverbank stabilization and coastal protection, geosynthetic rollers play a crucial role. They help in the installation of erosion control mats and fabrics, which prevent soil displacement and promote vegetation growth.

Landfills and Waste Management

- Geosynthetics are essential in landfill construction, where they are used to line and cap waste disposal sites. Geosynthetic rollers ensure the proper placement of geomembranes, preventing leachate contamination and gas migration, thus protecting the environment.

Mining and Tunneling

- In mining operations, geosynthetic rollers assist in the installation of liners for tailings ponds and heap leach pads. They also aid in tunnel construction by reinforcing tunnel linings and preventing water ingress.

Agricultural Applications

- Farmers use geosynthetic rollers to lay out materials that improve soil moisture retention, control weed growth, and prevent soil erosion. These applications are vital for sustainable agriculture and enhanced crop yields.

Benefits of Geosynthetic Rollers

Efficiency and Speed

- Geosynthetic rollers significantly reduce the time and labor required for material installation. Their automated and precise operation ensures that large areas can be covered quickly and consistently.

Cost-Effectiveness

- By improving installation efficiency and reducing material waste, geosynthetic rollers contribute to cost savings in construction and environmental projects. Additionally, the extended lifespan of structures reinforced with geosynthetics translates to lower maintenance costs.

Enhanced Performance

- The uniform placement of geosynthetic materials ensures optimal performance. This consistency leads to better load distribution, improved drainage, and increased soil stability, enhancing the overall quality of the project.

Environmental Sustainability

- Geosynthetic rollers promote sustainable construction practices by minimizing soil disturbance and reducing the need for traditional materials like concrete and steel. This approach not only conserves natural resources but also decreases the carbon footprint of construction activities.

The Future of Geosynthetic Rollers

The advancement of geosynthetic rollers is closely tied to the ongoing development of geosynthetic materials and automated construction technologies. Innovations such as smart rollers equipped with sensors and GPS technology are on the horizon, promising even greater precision and efficiency in material placement. Additionally, the integration of recyclable and biodegradable geosynthetics will further enhance the environmental benefits of this technology.

Conclusion

Geosynthetic rollers have become indispensable tools in modern construction and environmental engineering. Their ability to streamline the installation of geosynthetics, combined with the numerous benefits they offer, makes them a vital component in a wide range of applications. As technology continues to evolve, geosynthetic rollers will undoubtedly play an increasingly significant role in building sustainable and resilient infrastructure for the future.