Micro Injection Molded Plastic market size was valued at USD 1,166 million in 2022 and is projected to reach USD 3,500 million by 2033, growing at a CAGR of 11.4% during the forecast period. by We Market Research to get a stronger and more effective business outlook. It provides an in-depth analysis of the different attributes of the industry, such as trends, policies, and customers operating in different geographies. Research analysts use quantitative as well as qualitative analytical techniques to provide users, business owners, and industry professionals with accurate and actionable data.

Automobile demand is rising sharply in nations like South Korea, Japan, China, and India. The need for Micro Injection Molded Plastic in the automobile industry is being driven by this. Component size and weight reduction are becoming increasingly important to the automotive industry as a means of increasing fuel efficiency and optimizing performance. Because micro injection molding allows for the precise and repeatable manufacture of small, intricate plastic parts, it is suitable for use in miniature automobile applications. Micro injection molded plastic components are commonly utilized in the automotive industry in connectors, sensors, switches, microfluidic devices, micro-optics, and other critical elements used in electrical systems, lighting, interior controls, and safety features.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/micro-injection-molded-plastic-market/1160

Global Micro Injection Molded Plastic Market Definition:

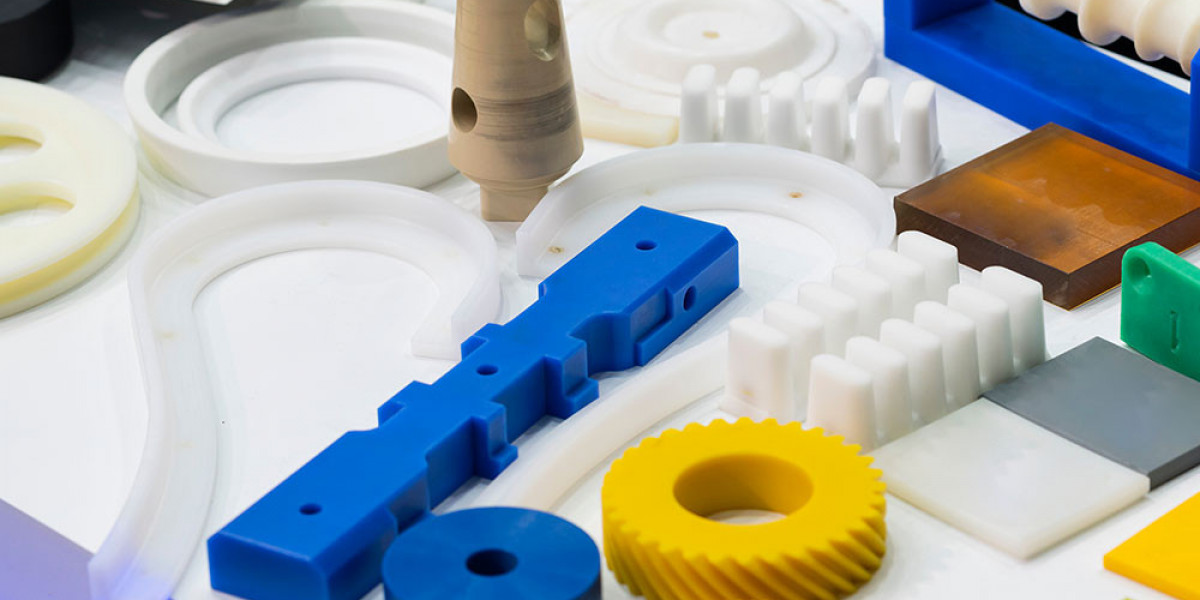

Micro injection molding is a molding technique for the manufacture of plastic components for shot weights of 1 to 0.1 grams with tolerances in the range of 10 to 100 microns. This molding technique enables the most precise and accurate manufacturing of complicated small geometries. The fundamental idea behind the micro injection molding technique is relatively similar to that of conventional injection molding. In this method, the injection molding machine includes a micro injection unit. Short dwell time, Low shear stress on the polymer melt, Homogeneous material preparation prior to molding, Precision injection, and ejection, and Accuracy of dimensions are some of the factors that influence machine and process technology when it comes to the manufacture of micro components

Key Companies Profiled In This Research Study Are:

- Proto Labs Inc.

- Accumold

- Microtech Precision

- MTD Micro Molding

- Makuta Micro Injection Molding

- American Precision Products

- Precimold; PTA Plastics

- Stack Plastics

- Plastikos Inc

Micro Injection Molded Plastic Market Segmentation:

North America

• U.S.

• Canada

• Mexico

Europe

• U.K.

• Germany

• France

• Italy

• Spain

• Rest of Europe

Asia Pacific

• China

• India

• Japan

• South Korea

• Australia

• Rest of Asia Pacific

South America

• Brazil

• Argentina

• Rest of South America

Middle East and Africa

• Saudi Arabia

• UAE

• Egypt

• South Africa

• Rest of Middle East and Africa

Micro Injection Molded Plastic Market Dynamics:

The market for micro injection molded plastic is expanding rapidly because more and more industries are requiring intricate and small-sized plastic components. This increase in demand can be attributed to a number of factors, such as advancements in technology, the need for superior quality and precision, and the trend toward smaller products. In response to growing consumer demands and market trends, the automotive, medical device, electronics, telecommunications, and consumer goods industries are aggressively searching for smaller, finely manufactured plastic parts.

Such high-performance plastic parts with precise designs and strict tolerances can be produced more easily thanks to micro injection molding. Furthermore, the growing need for intricate and compact plastic components in sectors including consumer goods, automotive, medical, electronics, and telecommunications drives the micro injection molded plastic

Opportunities: Rising Trend Of Electric Vehicles :

Micro injection molded plastic components are widely utilized in electric vehicles (EVs) because of their ability to meet the criteria of miniaturization, precision, and functional integration. The way that consumers view electric vehicles is evolving. As EV technology advances, consumers are becoming more receptive to the idea of electric transportation. Due to advantages including lower operating costs, quieter operation, and the availability of stylish, high-performance electric models, there is an increasing demand for electric vehicles. The market for micro injection molded plastics will be driven by the growing demand for electric automobiles.

Challenges:

Requirement of skilled personnel for the operation of micro injection molding machine: Because of its intricate operating structure, the production of micro injection molded items requires experienced workers. Because the applications for these molded plastics are so complicated, micro injection molded plastic parts used in the medical industry need special consideration and crucial processes. A significant obstacle encountered by producers in the micro injection molded plastic industry is the scarcity of proficient workers, particularly in industrialized nations.

Fastest Growing Material Type For Micro Injection Molding:

The market is also expected to experience modest increase during the projected timeframe. Market growth is probably going to be fueled by the growing use of electronic devices for medicinal purposes, micro components for electric vehicles, and other electronics-related components.

The micro-injection procedure PE, or thermoplastic polyethylene, is used in molding, particularly in the medical field. Physicians and surgeons use micro-instrumentation and injection-molded PE components to perform less intrusive treatments and expedite patient recovery. It is projected that during the forecast period, manufacturers' expenditures in R&D and innovation to enhance noninvasive device designs and decrease the size of the various components through micro-forming will drive an increase in demand for these small, highly precise devices.

Purchase a Copy of this Micro Injection Molded Plastic Market research report:

https://wemarketresearch.com/purchase/micro-injection-molded-plastic-market/1160?license=single

Related Reports

About We Market Research:

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep rooted market studies and insightful analysis of different markets.

Get More Insights: https://wemarketresearch.com/