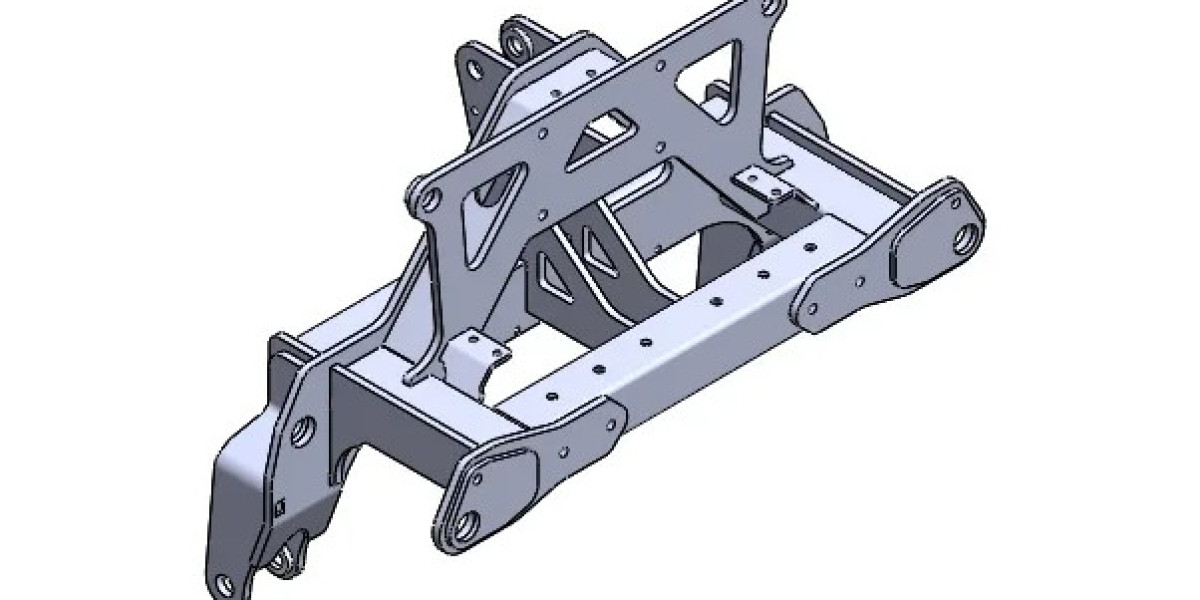

For those seeking a unique touch to their bicycle, a custom-made central frame can be the ideal solution. This specialized component not only enhances the aesthetics but also offers personalized features tailored to individual preferences. From choosing materials to specific design elements, a custom-made central frame provides cyclists with the opportunity to create a one-of-a-kind riding experience. Whether it's for performance improvements or simply to stand out in a crowd, investing in a custom central frame can elevate your biking journey to new heights.

Understanding the Custom-Made Central Frame

Benefits

Custom-made central frames offer precision and durability tailored to specific vehicle models, ensuring optimal performance and safety. They provide enhanced stability and structural integrity, reducing vibrations and enhancing overall driving experience.

Process

The process of creating a custom-made central frame involves meticulous measurements and engineering expertise to ensure a perfect fit. Skilled technicians utilize advanced tools and techniques to fabricate the frame according to precise specifications.

Materials

Custom central frames are typically crafted from high-quality steel or aluminum alloys, chosen for their strength and lightweight properties. These materials undergo rigorous testing to meet industry standards for safety and performance.

Installation

Installation of a custom-made central frame requires professional expertise to ensure proper alignment and connection to the vehicle chassis. Technicians carefully weld or bolt the frame into place, following manufacturer guidelines for a secure attachment.

Maintenance

Maintaining a custom central frame involves regular inspections for signs of wear, damage, or misalignment that could affect performance. Routine maintenance tasks include checking for corrosion, ensuring proper alignment, and addressing any issues promptly.

Importance of Customization

Personalized Design

Custom made central frames offer personalized design options, allowing individuals to tailor the frame to their specific needs. This customization aspect ensures that the frame fits perfectly within the intended space.

Creating a unique design for a central frame enables individuals to showcase their personality and style. By incorporating personal touches, such as favorite colors or patterns, the frame becomes a reflection of the owner's taste.

Enhanced Functionality

Customization enhances the functionality of central frames by catering to specific requirements. Whether it's adjusting the size, shape, or features of the frame, customization ensures that it serves its purpose effectively.

The ability to customize central frames according to technical specifications guarantees optimal performance. From accommodating specialized equipment to improving overall efficiency, customization plays a vital role in enhancing functionality.

Tailored Aesthetics

Tailoring the aesthetics of a central frame allows individuals to achieve a seamless integration with their existing decor. Customization offers the flexibility to choose materials, finishes, and details that complement the surrounding environment.

Benefits of Custom-Made Central Frames

Enhanced Structural Integrity

Custom-made central frames provide enhanced structural integrity due to their precise measurements and tailored design. This ensures a perfect fit for the specific vehicle, reducing the risk of misalignments or issues in the long run.

Custom central frames are engineered to distribute weight and stress evenly, enhancing the overall stability of the vehicle. By precisely fitting the vehicle's dimensions, these frames reduce the chances of structural damage during impacts or collisions.

Improved Performance and Handling

Tailored central frames contribute to improved performance and handling by optimizing the vehicle's weight distribution. This customization allows for better balance and control, resulting in smoother rides and more responsive steering.

Custom central frames can also be designed to accommodate specific modifications or upgrades, such as suspension enhancements or engine swaps. This flexibility enhances the vehicle's capabilities and overall driving experience.

Personalized Aesthetics

Opting for a custom-made central frame allows owners to personalize their vehicles according to their preferences. This customization offers endless possibilities in terms of design, finish, and additional features that align with individual styles and tastes.

Owners can choose unique paint colors, finishes, or even incorporate custom logos or graphics into their central frames. This level of personalization not only enhances the aesthetic appeal of the vehicle but also reflects the owner's personality and creativity.

Applications in Various Industries

Automotive Sector

Custom made central frames play a crucial role in the automotive sector by providing structural support and rigidity to vehicles. They are tailored to specific vehicle models, ensuring optimal performance and safety. In the automotive industry, these central frames are designed to withstand various road conditions and impacts, enhancing overall vehicle durability.

Central frames customized for electric vehicles are becoming increasingly popular due to the unique requirements of EV chassis. The integration of lightweight materials such as aluminum and carbon fiber in these frames helps reduce overall vehicle weight, leading to improved energy efficiency and range. Custom central frames contribute to the safety of electric vehicles by enhancing structural integrity and impact resistance.

Construction Industry

In the construction industry, bespoke central frames are utilized in building structures to provide stability and support. These custom-made frames are engineered to meet specific architectural requirements, ensuring structural integrity and load-bearing capacity. Central frames designed for high-rise buildings undergo rigorous testing to withstand wind loads and seismic activities, safeguarding the structure against external forces.

The customization of central frames in construction projects allows architects and engineers to optimize space utilization while maintaining structural strength. By tailoring central frames according to building specifications, contractors can streamline the construction process and minimize material wastage. This customization also enables flexibility in design, accommodating unique architectural features and layouts.

Aerospace Sector

In the aerospace sector, tailor-made central frames are essential components of aircraft structures, providing support for wings, engines, and other critical systems. These customized frames are engineered using advanced materials such as titanium alloys and composite fibers to ensure optimal strength-to-weight ratios. Custom central frames undergo stringent quality control measures to meet aviation regulatory standards for safety and performance.

The integration of custom central frames in aircraft manufacturing enhances aerodynamic efficiency and reduces overall weight, contributing to fuel savings and operational cost reductions. Aerospace companies rely on bespoke central frames to achieve precise alignment of aircraft components, ensuring aerodynamic stability during flight operations. Customized central frames enable aircraft manufacturers to optimize cabin space for passenger comfort while maintaining structural robustness.

Closing Thoughts

The versatility and tailored precision of custom-made central frames offer a myriad of benefits across various industries. From enhancing structural integrity to optimizing performance, the customization options available cater to specific needs, ensuring efficiency and reliability. Understanding the significance of personalized central frames underscores their pivotal role in modern engineering practices.

Exploring the applications and advantages of custom-made central frames illuminates their indispensable nature in diverse sectors. Embracing customization not only elevates functionality but also fosters innovation and adaptability in design and production processes. As industries continue to evolve, the utilization of bespoke central frames stands as a testament to the pursuit of excellence through tailored solutions.

Frequently Asked Questions

What is a custom-made central frame?

A custom-made central frame is a specialized component tailored to specific requirements, providing unique dimensions and features for various applications.

Why is customization important for central frames?

Customization ensures that central frames meet precise specifications, enhancing performance, durability, and compatibility with specific equipment or structures.

What are the benefits of using custom-made central frames?

Custom-made central frames offer improved functionality, better fitment, enhanced aesthetics, increased structural integrity, and optimized performance compared to standard off-the-shelf options.

In which industries can custom-made central frames be utilized?

Custom-made central frames find applications across diverse industries such as automotive, aerospace, manufacturing, construction, robotics, and more due to their versatility and adaptability.

How can one order a custom-made central frame?

Ordering a custom-made central frame typically involves consulting with manufacturers or fabricators specializing in customized metalwork to discuss design requirements and production specifics.