The global chelating agents market size is expected to grow at a CAGR of 3.8% during the period 2024-2032. Chelating agents, whether natural or synthetic organic compounds, play a crucial role in various industrial, medical, and biological applications. From aiding digestion in humans and animals to facilitating nutrient transportation in plants, their diverse functionalities ensure continued demand. Geographically, North America, Europe, and Asia are anticipated to be the key markets driving this growth, fueled by a thriving industrial sector and increasing environmental regulations.

This blog post delves into the fascinating world of chelating agents, specifically focusing on their indispensable role within various industrial processes. We'll explore their importance in metal cleaning, the pulp and paper industry, and the textile industry. We'll also analyze the different types of chelating agents and their unique properties. Finally, we'll discuss the environmental impact of these agents, ongoing efforts towards sustainability, and future trends in this ever-evolving market.

Importance of Chelating Agents in Industrial Processes

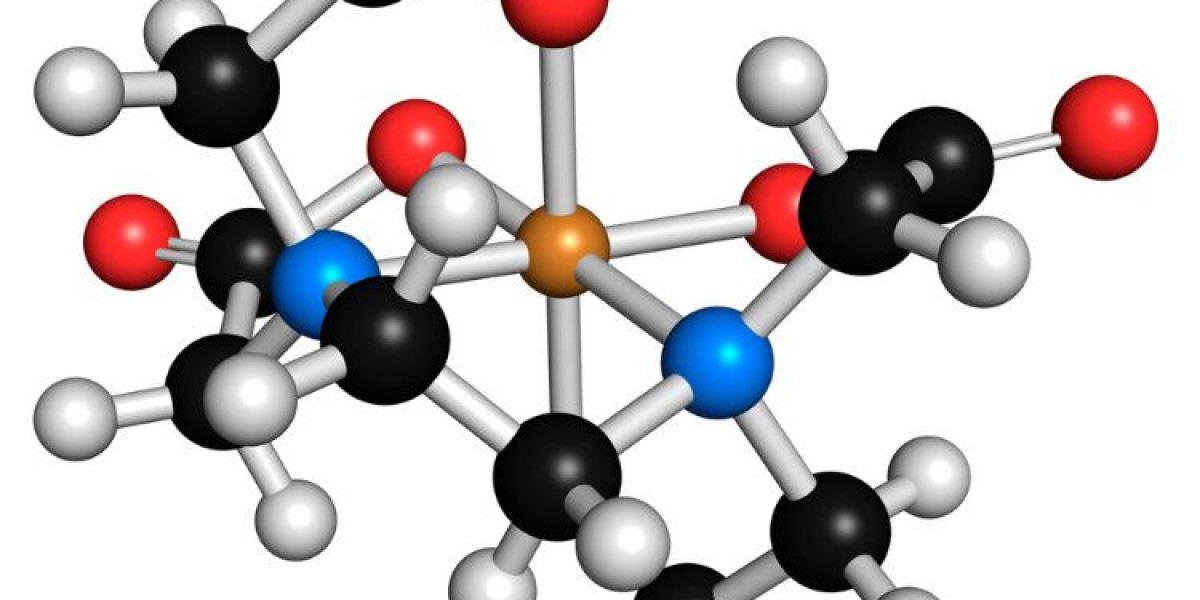

Chelating agents offer a multitude of benefits in industrial settings. Their primary function lies in their ability to form complexes with metal ions. These complexes, known as chelates, effectively "grab" metal ions with their molecular claws, rendering them inactive or easily removable. This characteristic makes them valuable tools across various industrial processes:

A. Metal Cleaning and Surface Treatment:

Removing Metal Stains and Scales: Industrial equipment often accumulates metal oxides, rust, and other contaminants on its surfaces. Chelating agents can effectively dissolve these unwanted minerals by binding to the metal ions, making them easier to remove through cleaning processes like rinsing or scrubbing. This not only improves the aesthetics of the equipment but also ensures its optimal performance by preventing surface irregularities and potential corrosion.

Preventing Corrosion: Corrosion, the deterioration of metals due to chemical reactions with their environment, poses a significant challenge in numerous industries. Chelating agents come to the rescue by forming complexes with metal ions that are prone to oxidation. These complexes hinder the interaction between the metal and corrosive agents like oxygen or moisture, thereby providing a protective layer and significantly extending the lifespan of machinery and infrastructure.

B. Use in Pulp and Paper Industry:

Improving Pulp Quality: The pulp and paper industry relies heavily on the quality of wood pulp, which is the primary raw material for paper production. Minerals present in wood, particularly iron and manganese, can negatively impact the quality of pulp by causing discoloration and hindering bleaching processes. Chelating agents, by selectively binding to these metal ions, remove them from the pulp, resulting in a cleaner and brighter final product.

Enhancing Paper Brightness: The brightness of paper is a key determinant of its quality. Chelating agents, by removing metal ions that can cause yellowing or browning, contribute to a whiter and more visually appealing paper product. This is particularly important for high-quality printing paper and graphic design applications.

Types of Chelating Agents

A diverse range of chelating agents cater to specific industrial needs. Here are some of the most commonly employed agents:

Ethylenediaminetetraacetic acid (EDTA): A highly versatile chelating agent, EDTA finds applications in various industries due to its strong binding affinity for a wide range of metal ions. However, its biodegradability is a concern.

Diethylene triamine pentaacetic acid (DTPA): Similar to EDTA, DTPA offers strong chelating properties with improved biodegradability compared to EDTA. This makes it a preferred choice in applications where environmental considerations are paramount.

Nitrilotriacetic acid (NTA): An eco-friendly alternative to EDTA, NTA exhibits good biodegradability and finds use in various industrial cleaning applications.

Citric Acid: A naturally occurring organic acid, citric acid serves as a biodegradable chelating agent. It is often employed in the food and beverage industry due to its non-toxic nature.

Environmental Impact and Sustainability

While chelating agents offer undeniable benefits in various industrial applications, their environmental impact requires careful consideration. A significant concern lies in their biodegradability. Some commonly used chelating agents, such as EDTA, are slow to decompose in the environment, potentially leading to bioaccumulation and ecological disruptions. Furthermore, the release of chelated metals into wastewater streams can pose a challenge, as the chelates may prevent the efficient removal of these metals during wastewater treatment processes.

A. Concerns over Biodegradability:

The limited biodegradability of some chelating agents can lead to their persistence in the environment. This can disrupt natural ecosystems as these agents continue to bind to essential metal ions needed by organisms for various biological processes. Furthermore, the presence of chelated metals in soil can hinder the uptake of vital nutrients by plants, potentially affecting agricultural productivity.

B. Efforts to Develop Eco-friendly Alternatives:

The growing awareness of environmental concerns has spurred the development of eco-friendly chelating agents. These agents are designed to be readily biodegradable, minimizing their environmental footprint. Some examples include DTPA, NTA, and citric acid, as mentioned earlier. These alternatives offer a more sustainable approach to industrial processes while maintaining the desired chelating properties.

Future Trends and Innovations

The chelating agents market is continuously evolving, driven by advancements in research and development. Here are some exciting trends shaping the future of this industry:

A. Development of New Chelating Agents:

Research efforts are focused on developing next-generation chelating agents with enhanced properties. These agents will offer even greater selectivity for specific metal ions, improved biodegradability, and potentially even higher chelating capacity. Additionally, the development of agents tailored for specific industrial applications will further optimize process efficiency and minimize environmental impact.

B. Application in Emerging Industries:

The use of chelating agents is expected to expand beyond traditional industries. For instance, the growing electronics industry requires high-purity materials. Chelating agents can play a vital role in this sector by removing trace metal impurities, ensuring the optimal performance and reliability of electronic components.