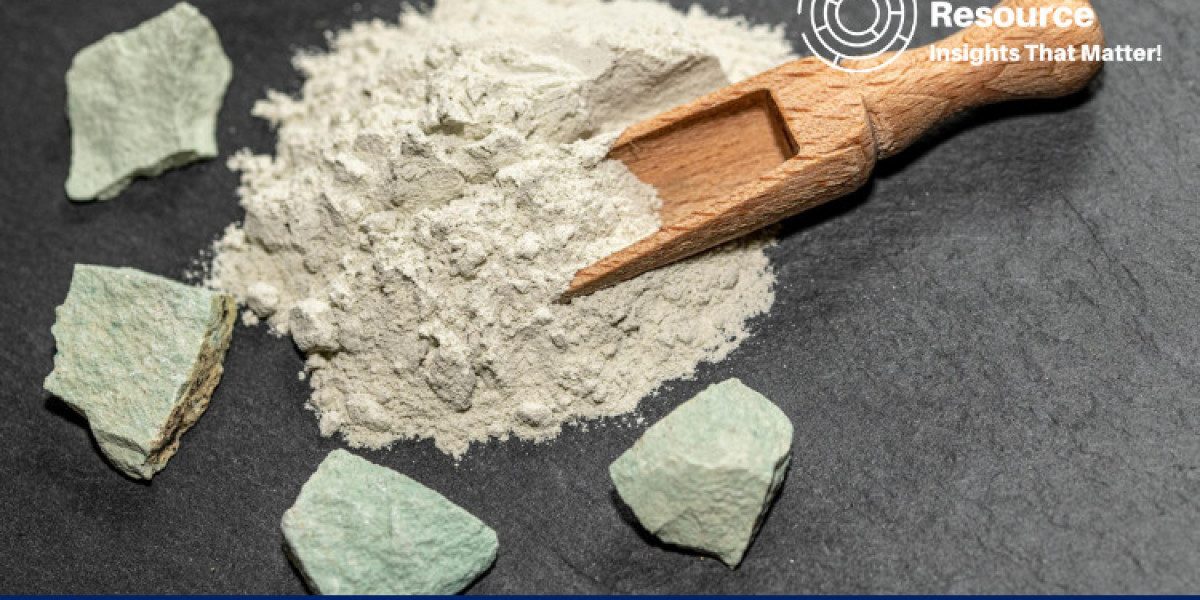

In the realm of industrial chemistry and environmental remediation, zeolites stand out as remarkable materials with a plethora of applications. These crystalline aluminosilicates possess unique molecular structures, offering exceptional adsorption properties, ion exchange capabilities, and catalytic activities. From water purification to petrochemical refining, zeolites play a pivotal role in various sectors. However, as with any production process, understanding the economics behind zeolites production is crucial for maximizing efficiency and sustainability.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/zeolites/request-sample

Zeolites Production: A Brief Overview

Before delving into the cost analysis, it's essential to grasp the fundamentals of zeolites production. Zeolites are primarily synthesized through two main methods: natural extraction and synthetic production. Natural zeolites are mined from deposits formed over geological timescales. On the other hand, synthetic zeolites are manufactured in controlled laboratory or industrial settings.

Natural Extraction vs. Synthetic Production

Natural zeolites, while abundant in certain regions, often require extensive processing to meet desired purity and particle size specifications. This processing contributes significantly to the overall production cost. Conversely, synthetic production offers more control over zeolite characteristics, allowing for tailored properties to suit specific applications. However, the synthetic route entails higher initial investment in infrastructure and raw materials.

Zeolites Production Cost Analysis

Conducting a comprehensive cost analysis is imperative for optimizing production processes and identifying potential areas for efficiency improvement. Several key factors influence the overall cost of zeolites production:

Raw Materials: The cost of raw materials, including silica and alumina sources, as well as chemicals for synthesis and purification, constitutes a significant portion of production expenses.

Energy Consumption: Both natural and synthetic zeolites production processes require substantial energy inputs, particularly during heating and drying stages. Utilizing energy-efficient technologies can mitigate these costs.

Labor Costs: Skilled labor is essential for operating production facilities, conducting quality control checks, and troubleshooting process issues. Labor costs vary depending on location and workforce expertise.

Capital Investment: Initial capital expenditure for equipment, infrastructure, and research and development activities represents a substantial portion of production costs, particularly for synthetic production facilities.

Environmental Regulations: Compliance with environmental regulations adds another layer of cost, especially concerning waste management, emissions control, and sustainable resource utilization.

Zeolites Production Cost Analysis Report

A detailed cost analysis report provides invaluable insights into the economic viability of zeolites production. It enables stakeholders to:

- Identify cost drivers and areas for optimization.

- Benchmark production costs against industry standards.

- Evaluate the feasibility of scaling up production capacity.

- Formulate strategies for cost reduction and process improvement.

- Assess the impact of market dynamics on production economics.

Moreover, continuous monitoring and periodic reassessment of production costs ensure adaptability to changing market conditions and technological advancements.

Conclusion

Zeolites production plays a pivotal role in various industrial applications, offering versatile solutions for environmental and catalytic challenges. Understanding the economics of zeolites production through thorough cost analysis is essential for maximizing efficiency, sustainability, and profitability. By optimizing raw material sourcing, energy utilization, labor efficiency, and capital investment, stakeholders can unlock the full potential of zeolites as a cornerstone of modern chemistry and engineering.