The production of Fatty Alcohol C12 is an intricate and evolving process, demanding a comprehensive understanding of its cost analysis to optimize profitability and efficiency. In this detailed guide, we delve into the fatty alcohol C12 production cost processes, providing a clear perspective on the various elements that play a pivotal role in shaping the costs associated with its production. This report aims to serve as an invaluable resource for stakeholders, ranging from manufacturers to investors, who are keen on gaining insights into the production cost processes of Fatty Alcohol C12.

Procurement Resource Assessment of Fatty Alcohol C12 Production Process

Overview of the Production Process

Fatty Alcohol C12, also known as Dodecanol, is a prominent member of the fatty alcohol group, widely utilized in various industries. The production of Fatty Alcohol C12 involves several key stages, each contributing to the overall cost:

Raw Material Acquisition: The primary raw materials used in the production of Fatty Alcohol C12 include natural fats and oils, such as palm oil or coconut oil. The cost and availability of these materials can significantly influence the production cost.

Processing and Refinement: The transformation of raw materials into Fatty Alcohol C12 involves processes like hydrolysis and hydrogenation. The efficiency, technology, and energy consumption in this phase play a crucial role in determining production costs.

Quality Control and By-Product Management: Ensuring the purity of Fatty Alcohol C12 and managing by-products efficiently can impact the overall cost-effectiveness of the production process.

Request Free Sample: https://www.procurementresource.com/production-cost-report-store/fatty-alcohol-c12/request-sample

Cost Analysis Components

In assessing the cost of production, several factors are considered:

- Raw Material Costs: Fluctuations in the price of natural oils and fats.

- Labor and Operational Expenses: Costs related to manpower, facility maintenance, and daily operations.

- Technology and Equipment: Investment in advanced technology for efficient processing.

- Energy Consumption: The energy requirements of the production process.

- Regulatory Compliance: Costs associated with adhering to environmental and safety regulations.

Strategic Sourcing and Procurement

Effective sourcing strategies for raw materials and an efficient procurement process can significantly reduce the overall production cost. The assessment involves analyzing market trends, supplier reliability, and negotiating favorable terms.

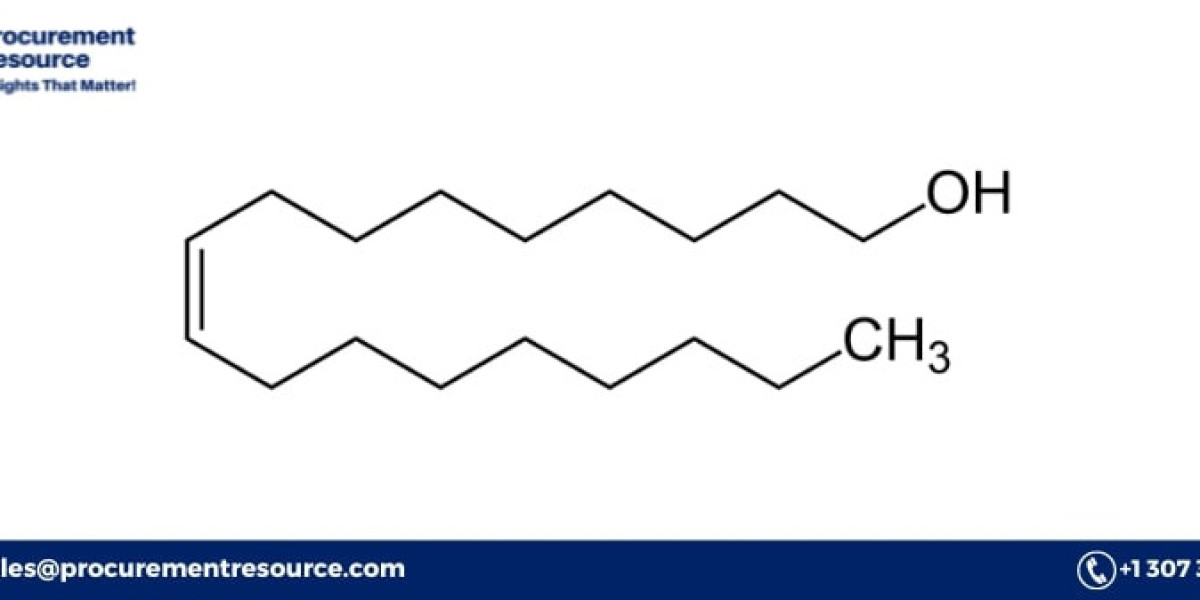

Definition of Fatty Alcohol C12

Fatty Alcohol C12, known chemically as Dodecanol, is a fatty alcohol derived from natural sources like palm kernel oil or coconut oil. It appears as a colorless, waxy solid and is characterized by its biodegradable and non-toxic properties. Fatty Alcohol C12 finds extensive applications in industries such as cosmetics, food, pharmaceuticals, and detergents due to its emulsifying, moisturizing, and stabilizing properties.

Market Drivers

Several factors drive the market for Fatty Alcohol C12:

- Growing Demand in Personal Care and Cosmetics: With the burgeoning personal care industry, the demand for natural and sustainable ingredients like Fatty Alcohol C12 is on the rise.

- Industrial Applications: Its use in detergents, industrial cleaners, and lubricants fuels its market growth.

- Shift Towards Bio-based Products: The global shift towards sustainable and bio-based products augments the demand for Fatty Alcohol C12.

- Regulatory Support: Government regulations favoring environmentally friendly and sustainable products boost the market for Fatty Alcohol C12.

Comprehensive and Personalized Reports for Business Augmentation

In today's competitive business landscape, having a tailored and exhaustive report on Fatty Alcohol C12 production cost analysis is crucial. These reports provide deep insights and are instrumental in:

- Strategic Decision Making: Empowers businesses to make informed decisions regarding investments, production scaling, and market entry.

- Cost Optimization: Identifies areas where costs can be reduced without compromising on quality.

- Market Trend Analysis: Keeps businesses abreast of market trends, helping them to stay ahead of competitors.

- Risk Management: Assesses potential risks and prepares businesses to mitigate them effectively.

In conclusion, understanding the cost analysis of Fatty Alcohol C12 production is vital for businesses operating in this domain. It helps in optimizing production processes, making informed decisions, and ultimately achieving sustainable growth and profitability. This report serves as a comprehensive guide, providing detailed insights into every aspect of Fatty Alcohol C12 production cost processes, making it an indispensable tool for businesses looking to thrive in this sector.